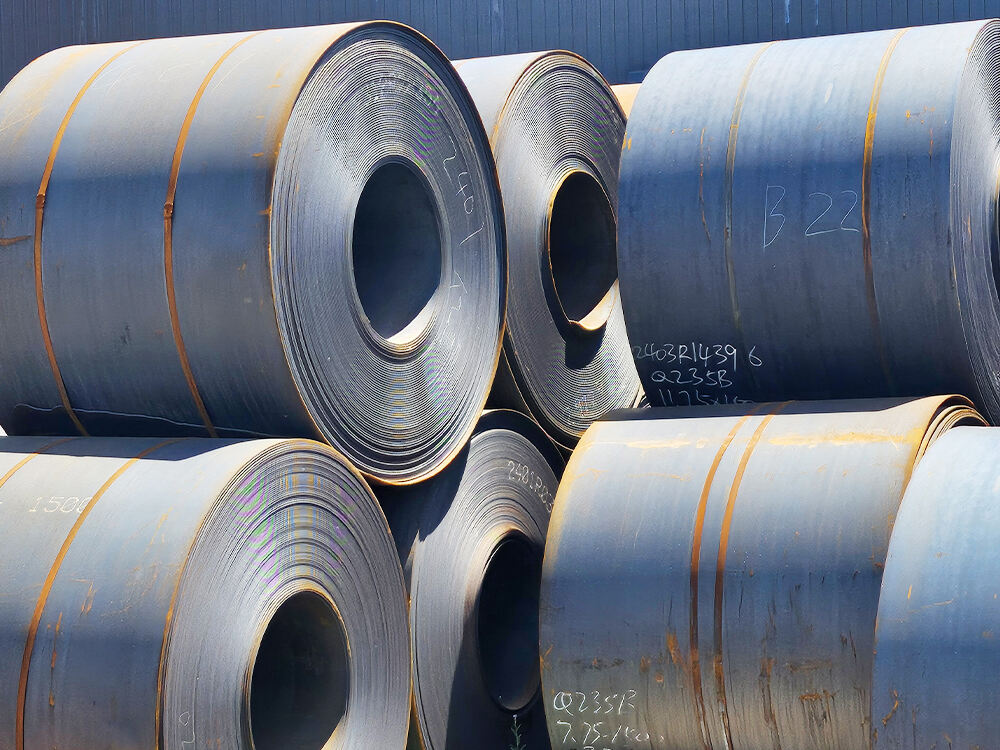

Hot rolled carbon steel coil

The main components of hot rolled carbon steel coil are iron and carbon, usually containing small amounts of elements such as manganese, silicon, sulfur and phosphorus. During hot rolling, steel is processed at high temperatures (usually above 1000°C). After the billet is heated to a high temperature, it is rolled into shape and cooled to form a coil. Due to high temperature processing, hot rolled steel has larger grains, a rougher internal structure, lower precision, and poorer mechanical properties, strength, and toughness. However, because of its high production efficiency and low cost, it can withstand high temperature and high stress environments and is widely used in bridges, buildings, ships and other fields.

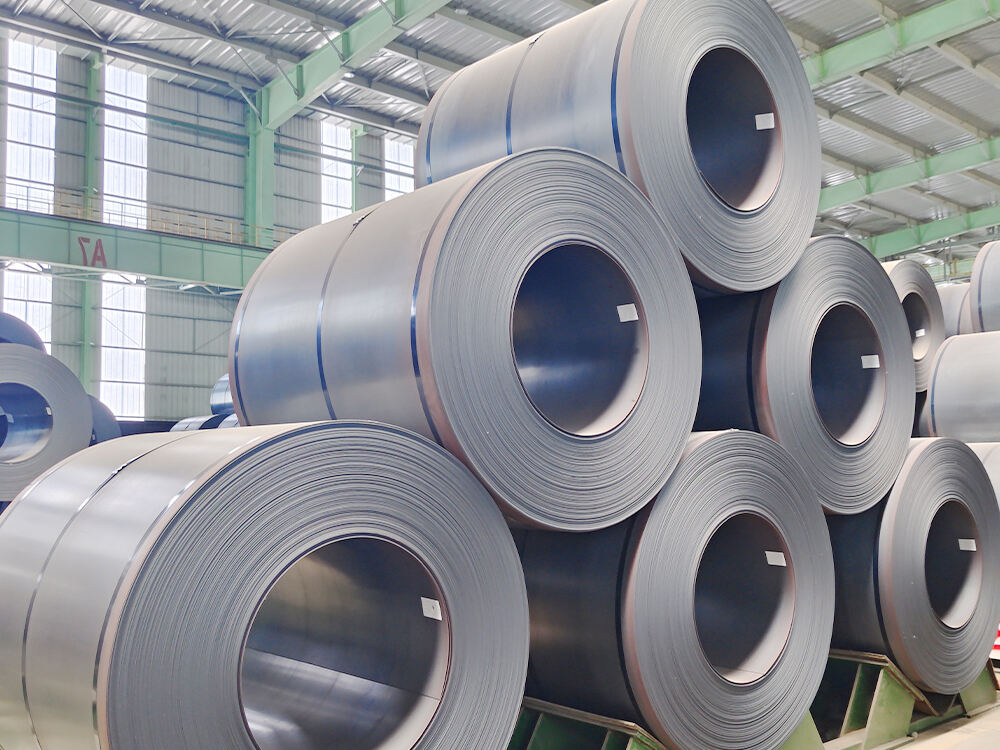

Cold rolled carbon steel coil

Cold rolled carbon steel coil is similar to hot rolling, but during the cold rolling process, some alloying elements may be added to improve performance. Hot rolled coils are further processed at room temperature, usually by rolling and stretching to improve strength and precision. Cold rolled steel has finer grains, smoother surfaces and higher dimensional accuracy. Because of its smooth surface, high precision, excellent mechanical properties, and easier subsequent processing and coating treatment, it is widely used in home appliances, automobile housings, precision parts and other products with high requirements on appearance and size.