Carbon Steel Spiral Pipe

Carbon steel pipes are divided into spiral pipes, welded pipes, and seamless pipes according to the welding method. Welded pipes have high welding strength and can withstand greater pressure and impact. Seamless pipes have no welds and strong pressure bearing capacity, which is suitable for high temperature and high pressure environments.

- Overview

- Product Parameters

- More Details

- FAQ

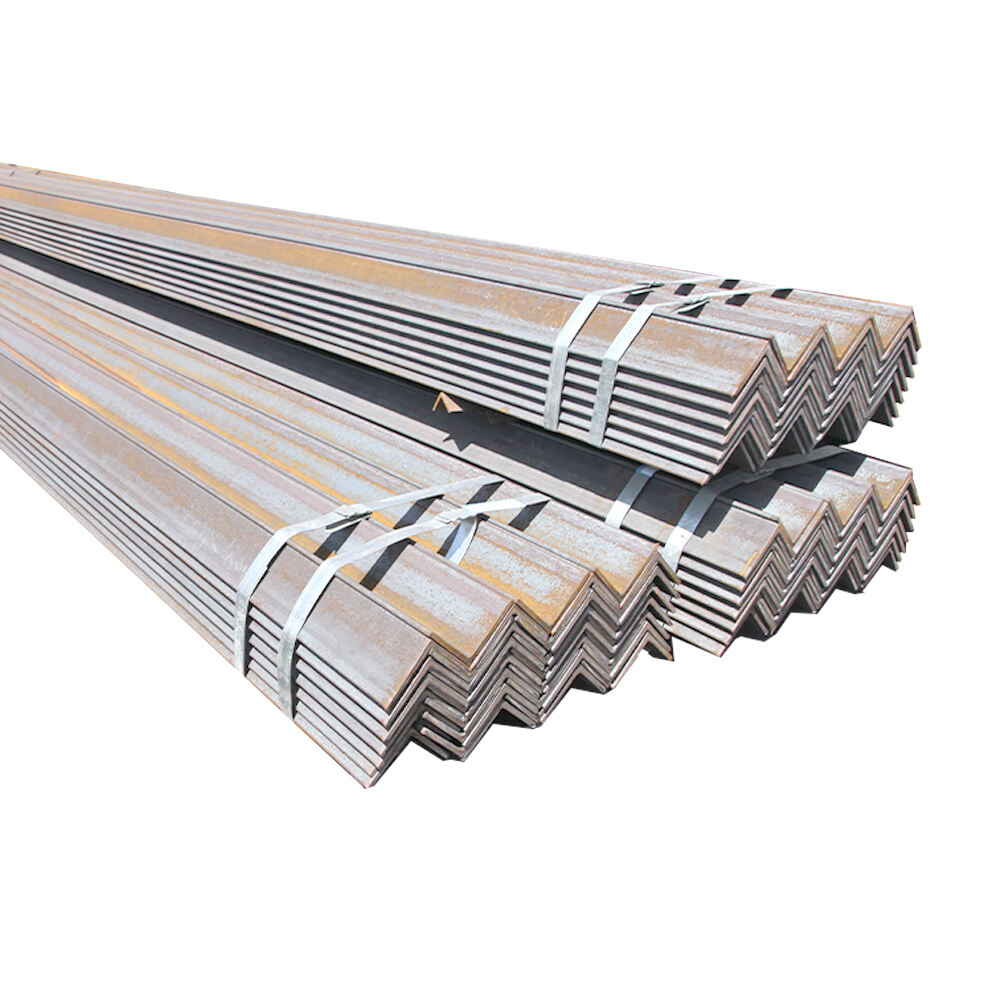

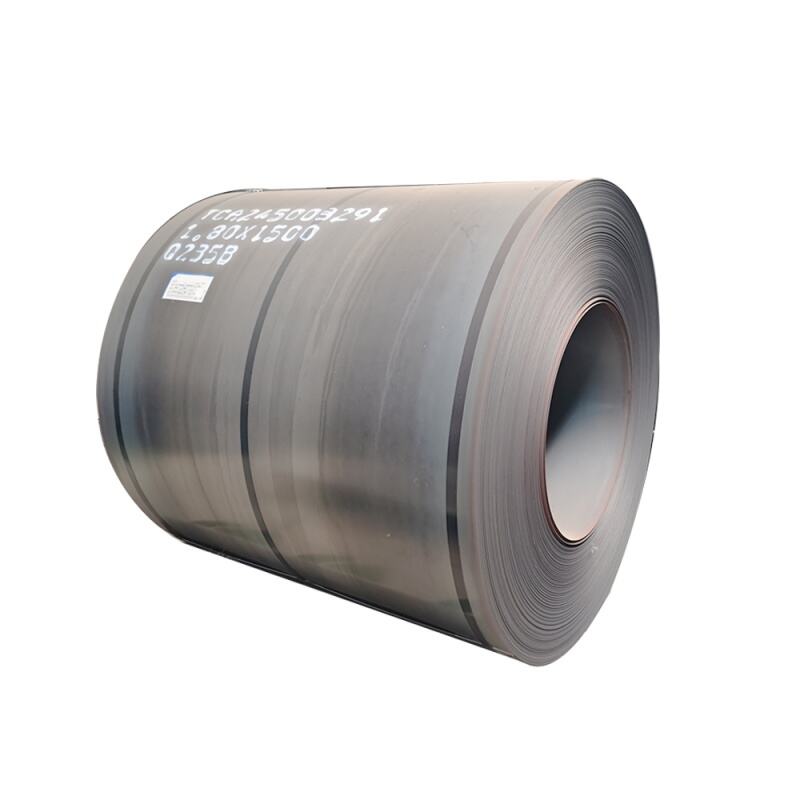

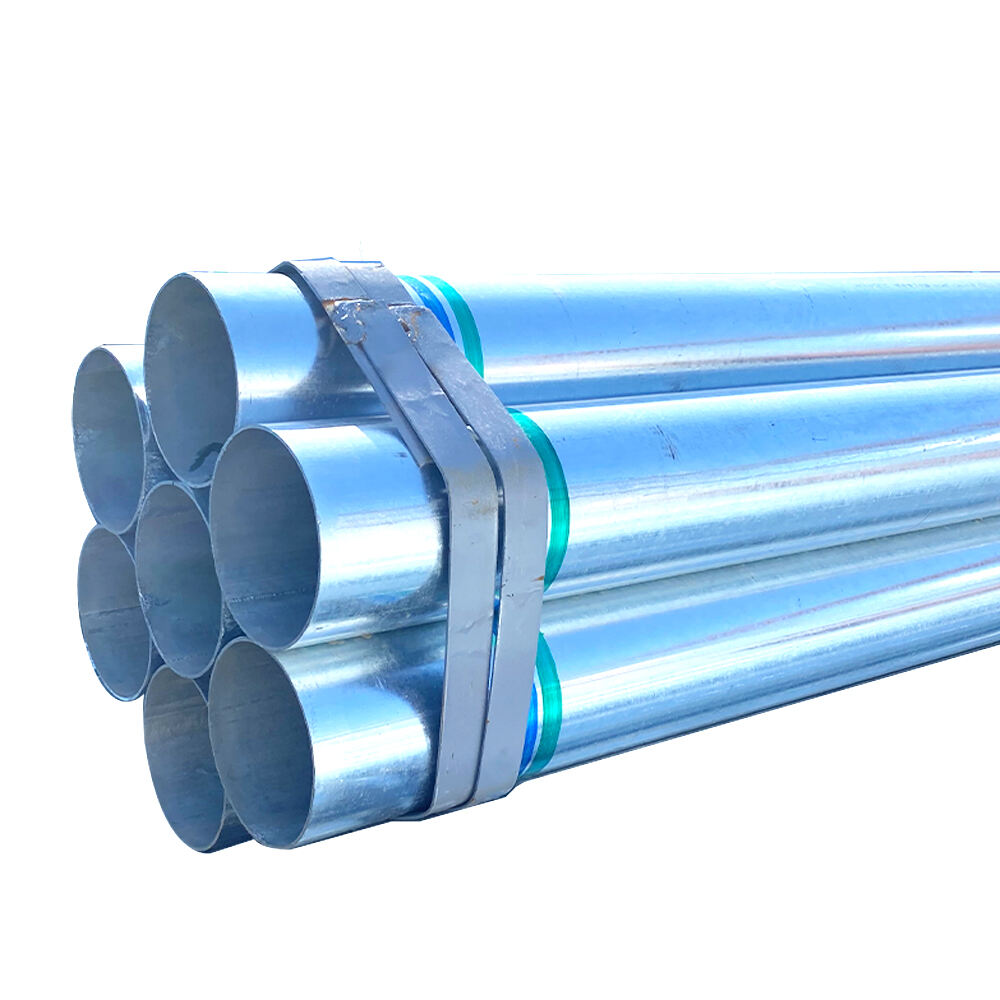

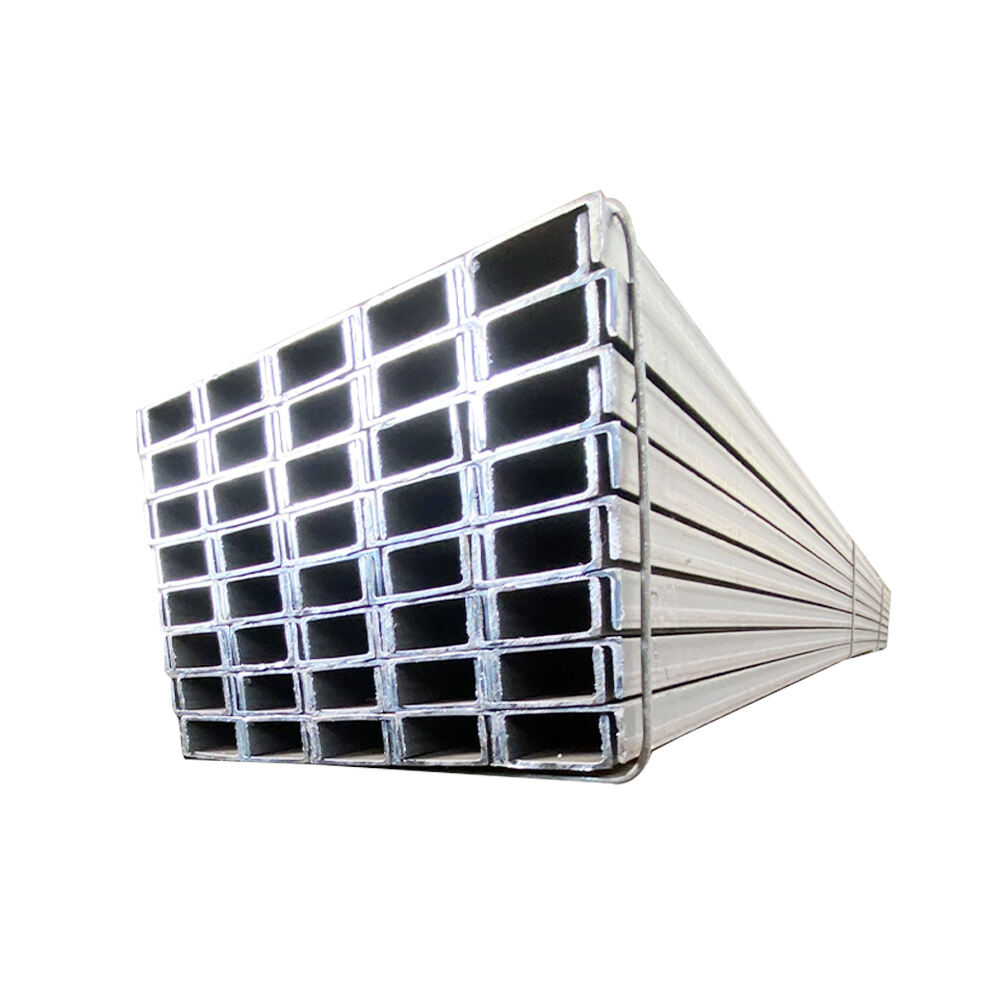

- Related Products

1. High strength and toughness

Carbon steel spiral welded pipes are made of high-quality carbon steel materials, have good strength and toughness, can withstand greater pressure and impact, and are suitable for high-load conditions.

2. Large-diameter production capacity

The spiral welding process makes it possible to produce large-diameter pipes, which are suitable for occasions where large flow rates are required, such as the transportation of oil, natural gas and water.

3. Good welding performance

Due to the spiral shape of the weld, the welding strength is high, which can effectively prevent defects at the weld and improve the reliability of the overall pipeline.

4. Economic efficiency

Compared with seamless pipes, spiral welded pipes have lower production costs and are suitable for large-scale production. They can reduce costs while meeting quality requirements and provide more competitive prices.

5. Flexible specifications

Carbon steel spiral welded pipes can be customized in different specifications and sizes according to customer needs to meet the needs of various engineering projects.

6. Corrosion resistance

Through surface treatment (such as painting or galvanizing), spiral welded pipes can improve corrosion resistance, extend service life, and adapt to harsh environments.

7. Easy installation

Spiral welded pipes have various connection methods and are easy to install, which can effectively shorten the construction period and improve construction efficiency.

Product Parameters

|

Product name |

Spiral Carbon Steel Pipe |

|

Material model |

Q195, Q235, Q345, X42, X52, etc. |

|

Diameter range |

219 mm - 3000 mm |

|

Wall thickness range |

5 mm - 25 mm |

|

Length |

6 m, 12 m, customizable |

|

Welding process |

Spiral welding (SAW or ERW) |

|

Tensile strength |

≥ 355 MPa |

|

Yield strength |

≥ 245 MPa |

|

Elongation |

≥ 20% |

|

Hardness |

≤ 160 HB |

|

Surface treatment |

Hot-dip galvanizing, spraying, polishing, etc. |

|

Applicable temperature |

-40°C to 450°C |

|

Applicable pressure |

≤ 20 MPa |

|

Quality standard |

API 5L, ASTM A53, GB/T 9711, etc. |

|

Delivery status |

Hot rolling, cold rolling, heat treatment |

|

Application area |

Petroleum, natural gas transportation, water treatment, construction, etc. |

More Details

FAQ

Q:Can I get samples before order ?

A: The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: How do we trust your company?

A: We specialise in steel business for years, headquarter locates in Jinan, Shandong province, you are welcome to investigate in any ways, by all means, you could place an order with trade assurance which could secure your payment.

Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile, Facebook, Skype, Wechat and WhatsApp will be online in 24 hours. Please send us your requirement and order information, specification(steel grade, size, quantity, destination port), we will work out a best price soon.

EN

EN